Coolant Filtration System

Home > Products > Filtration Products

Filtration Products

Hydorcyclone

•

Airsys has its classification technology and solid/liquid and liquid/liquid separation technology

embodied in wet-type cyclones.

•

Airsys is one of the two companies that are capable of developing

geometrical modeling designs of wet-type cyclones in the world.

•

Liner insert type cyclones have a structure that allows for insertion of an

insert of abrasion-resistant material onto the housing whereby the liner canbe

replaced for continuous use.

•

This system enables easy changes in line with particle sizes through the modification

of its components.

•

Liner materials include natural and synthetic rubber, urethane rubber, abrasion-

resistant steel, and ceramic.

•

It also supplies liners of silicon carbide.

•

In general, such parts as feeder chamber, cylinder, and long cone use materials that can provide

cushion in order to deal with impact wear caused by dispersed particles, while such parts as short

cone and apex adopt rigid materials in order to resist the slip wear caused by concentrated slurry.

•

Classification in wet-type milling

machines

•

Cleaning

of minerals,

ore dressing (gold)

•

Wet desulfurization process

•

Production of abrasives

•

Oil sand

•

Plastic recycling

•

Classification of polishing agent

•

LCD grinding slurry, cerium

•

Crystallization process, dissolution

& precipitation

•

Ceramic

•

Classification of blasting/grinding slurry

•

Classification in steel milling process

•

Production of abrasives

•

Purification of coolants

•

Removal of impurities in beverages

•

Removal of impurities in pulp

•

Removal of starch, sand, and

impurities

•

Cleaning of sand and dredged soil

•

Sand-lifting

•

Cleaning of polluted soil

•

Oil-based feedstock

Minerals, Petroleum products, Energy

Electronics, Steelmaking, Automobile, Chemicals,

Food, Sand, Soil

Applications

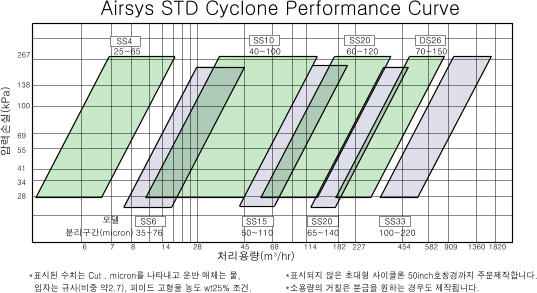

Standard cyclone

(with abrasion-resistant liner)

All-metal cyclone

(of high-temp/abrasion

-resistant materials)

Capacity

Crystallization & precipitation

(fertilizers, ceramics),

removal of fungal cells (lysine)

High-purity carbon black

manufacturing process

Wet desulfurization process

in power plants (WFGD)

Cleaning of soil and oil sand

Plastic recycling, removal

of impurities in ABS resin

LCD grinding, semiconductor

package sawing

Wet milling, Steel mill

(Classification & concentration)

Cleaning, liftingand

classification of sand

in sand plants

China

Japan

Korea

*You are viewing pages in English