Coolant Filtration System

Home > Products > Coolant Filtration

Filtration Products

Cyclone Separator

Gravity Filter(Dewatering)

CCS Oil Separation

Central Coolant Filtration (Gsep)

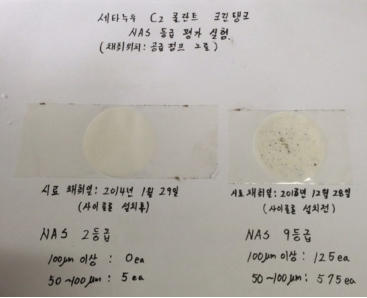

• Improves the cleanliness of NAS9 to NAS3, as shown in examples installed in aluminum

cutting processes in automobile engine lines.

• Deals effectively with part seating monitoring errors (prevention of the clogging of nozzles)

• This system consumes a small amount of filter paper: Sludge cake’s thickness: ≥5mm

• Operates without much difficulty and requires few devices.

• Requires little maintenance.

• Accommodates an additional system to forcefully agitate a central tank.

Theta Nu Block CCS2

Gamma Head CCS

Full view of the installation

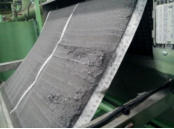

Thickness of cake on AGF filter

; 15~20mm.

Nas9

Nas2~3

Before

After

Before installation

After 1 month operation

Change of cleanliness : NAS9 -> 2

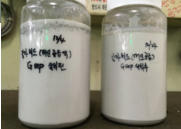

Before

After

Change in the fluid fed to the machine

Before installation

14’1204

After 10 days

operation

14’1214

NAS12

NAS5

Cake thickness on AGF filter

; about 10mm

Change in the fluid fed to the machine

This system is designed to circulate and filter liquids in central cleaning tanks.

This system can make visible improvement in the clogging of pipes and nozzles and

damage to shaft seals by chips and particles and their deposition.

* A combination of this system with an Oilsep system will achieve an ideal management of

central tanks.

The cleanliness is improved immediately with the installation of a system

having one quarter capacity of that for a central coolant filtration system.

China

Japan

Korea

*You are viewing pages in English