Coolant Filtration System

Home > Products > Coolant Filtration

Filtration Products

Oil Separation

Floating Skimmer

Central Coolant Filtration

Central Coolant Oil Separation(OilSep)

• Provides solutions to such small troubles relating to a centralized machine as

shaft seal breakage, poor seating, clogging, or trapped mucous matter.

• Reduces maintenance drastically.

• Frees itself from pollution, vile odor, and other environmental problems.

• Removes not only oil content but also fatty acids and protein that cause

the decomposition of cutting oil.

• Improves the service life of cutting oil.

• Gets rid of suspended chips.

• Furthermore, consumes few consumables,

uses little operating labor, and requires little maintenance.

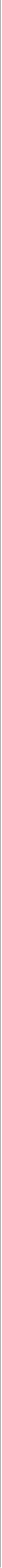

Change in contamination in a machine before or after installation

Before installing an oil separator

After installation (in 6 months)

* Result of the installation at Theta engine line

Reduction in fatty acids and protein: leads to a reduced risk of

cutting oil getting deteriorated.

Hyundai Ulsan Theta Nu Head C1

Change occurring in tanks

Change occurring in tanks

View of the installation Changes in the fluid fed to the machine

Tank for collected and concentrated oil

Centrifugal separation of the fluid fed to

the machine: Reduction in fatty acids and protein

Central separation system for Theta Crank at Hyundai Asan Plant

Skimmer inlet

Collected chips

(80Lr/day)

Inlet for oil/water

separation

(solid/liquid

separated water)

Treated

water

Concentrated oil

Waste oil

(80Lr/day)

Before

concentration

China

Japan

Korea

*You are viewing pages in English