Coolant Filtration System

Home > Products > Filtration Products

Filtration Products

Centrifuges (Auto/Manual)

•

Filtration of honing, grinding,

mineral oils

•

Paint factories

•

Quenching oil

•

Vibration surface treatment

•

Wire drawing

; AL,STS,Cu

•

Quenching oil

•

Gearbox oil

•

Refinement of mineral oils

•

TDI Desalt

•

Washer

•

Semiconductor packaging sawing

•

Glass cutting

•

Purification of potato chip washing water

•

Oil-based feedstock

Automobile engine, Costing

Steelmaking, Steel plates, Steel wire

Emiconductor, Electronics, Chemicals

Applications

•

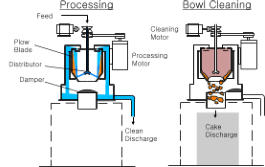

Detects the quantity of cake collected in the bowl and proceeds to clean it automatically,

improving its operation rate.

•

Senses excessive vibration and performs automatic balancing.

•

Adopts such advanced technologies as bearings cooling and foreign matter jamming prevention.

This system can be custom-tailored to fit in for severe service conditions up to 240’C.

•

Is the only centrifuge that is applicable to the hydrolysis process that uses critical water

; it was successfully developed the first time in the world.

•

Removes particles more effectively than other centrifuges such as screw decanters can.

Applicable to semiconductor wafer abrasives manufacturing processes and nano-slurry classification.

•

Has MF models that discharge cakes manually.

They detect excessive vibration and signal cleaning periods automatically.

This system is designed to feed liquid into the turning bowl and apply restrictive centrifugal force,

improving its centrifugal efficiency. It scrubs collected cakes and discharge them automatically.

AF300 Demo(Movie)

Treatment of potato chip washing water

Chemicals: Super-critical water

at TDI desalt process

China

Japan

Korea

*You are viewing pages in English